Flexural strengthening of a reinforced concrete road bridge

Description

A stone arch bridge was widened on one side between 1950 and 1970 by a reinforced concrete construction consisting of 2 girders and 1 parapet. The girders rest on abutments and are connected by struts and a concrete slab. At the bottom girder surface, the concrete is carbonated and the internal reinforcement partially corroded.

Furthermore, when applying the current standards according to SIA 269/1 (Table 1: aqi = 0.7, aQ1 = 0.7 and aQ2 = 0.5), it is found that the construction has a significant load carrying capacity deficit, especially when traffic loads are applied to the walkway as required by SIA 261 and 269/1. For this reason, and in view of the planned geometric adjustment, it was agreed with the owner that traffic would not be allowed to circulate on the pavement. The installation of road bollards between the traffic lane and the pavement is recommended.

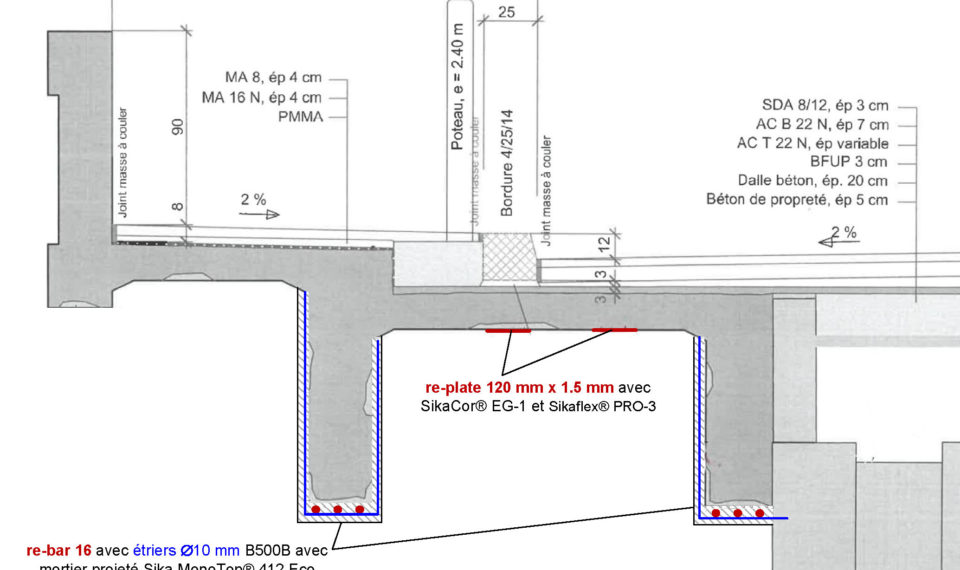

However, a reasonable reinforcement of the longitudinal beams is still required and must be carried out to meet the requirements of standards SIA 269 and others. A robust strengthening measure with the aim of extending the life expectancy of the bridge superstructure was carried out. The damaged excess concrete in the area of the reinforcement was removed by hyrodemolition. The surface was roughened as a base for the sprayed mortar Sika MonoTop® 412 Eco. On the tension side of the two bending beams, three re-bar 16 with a total prestressing force of 6 x 67.6 kN = 400 kN were applied and activated with gas. In the area of the 1 m long end anchorage, U-shaped stirrups made of structural steel B500B were arranged over the height of the web. A robust anchorage of the bending reinforcement in the compression zone was thus created. Prestressing of the stirrups was not required, as the load-bearing capacity of the internal shear reinforcement was jduged sufficient.

Static calculations showed that an additioanl reinforcement of the slab between the struts in longitudinal direction was necessary. This reinforcement was carried out by means of two pre-tensioned re-plates per segment. The strips were mechanically anchored to the core concrete. The concrete quality of the supporting base was checked with a concrete testing hammer. The required concrete compressive strength > 35 N/mm2 was present. The underside of the bridge slab was repaired with Sika MonoTop®, grain size 2 mm, before strengthening with re-plate was carried out. The external prestressing partially closes tensile cracks in the damaged concrete cover on the tensile side and prevents the ingress of pollutants such as water. The reinforcing strips were coated with SikaCor® EG-1 corrosion protection at the factory. To protect the coating during application, a glass mat was placed underneath in the area of the mechanical end anchorage and partially in between. On the sides, re-plate was sealed with Sikaflex® PRO-3 joint sealant. This prevents water and chlorides from penetrating behind re-plate. Since re-plate was activated with the infrared emitter, the posttensioning force for two external strips is 2 x 54 kN = 108 kN.

re-fer Product

6 x 13 m re-bar 16 and 12 re-plate with SikaCor® EG-1 corrosion protection

Year

2021

Contractor

Marti arc jura, re-fer AG

Info

Flexural Strengthening

Engineering consultant

GVH-BP Jura SA, 2800 Delémont

Bridge owner

Service des Infrastructures (SIN), Kanton Jura